ARTP作为比较基因组学的重要研究工具 成功应用于光滑球拟酵母CCTCC M202019

来源: 作者: 发布时间:2017-08-04 11:31 浏览量:547

本期向您推荐江南大学陈坚、堵国成、周景文教授科研团队,利用ARTP技术筛选高产丙酮酸菌株,却意外发现突变株产α-1,4-糖苷键的新型多糖。经过对多糖的成分及其合成途径的关键基因进行分析,揭示了多糖高效合成,丙酮酸低效转化,及丙酮酸发酵后期糖异生的原因。本研究2017年3月发表在《Appl Microbiol Biotechnol》上(文章题目:Identification of a polysaccharide produced by the pyruvate overproducer Candida glabrata CCTCC M202019)。

丙酮酸是一种重要的有机酸,广泛应用于制药、农业化学和食品等工业。丙酮酸常用的生产方法有化学合成法,酶转化法和微生物发酵法。发酵法生产丙酮酸具有低成本,高质量,对环境的友好等优点,是丙酮酸工业化生产的发展方向。

江南大学陈坚、堵国成、周景文教授科研团队长期致力于丙酮酸发酵生产研究,前期已获得了球拟酵母多重维生素营养缺陷型菌株——光滑球拟酵母CCTCC M202019(烟酸、硫胺素、吡哆醇和生物素4中维生素营养缺陷菌),该菌株能大量生产丙酮酸并分泌到胞外。为了提高底物相对转化率,进一步提高丙酮酸产量,采用ARTP技术对光滑球拟酵母CCTCC M202019进行诱变,筛选得到突变株4-C10。该突变株的培养基摇瓶发酵60 h后,在室温(约15℃)下经过0.5小时自发固化,其发酵产物提取纯化后为白色粉末S4-C10。后经酸水解、α-淀粉酶消化、葡糖淀粉酶和纤维素水解,及傅里叶变换红外等分析表明,白色粉末S4-C10由1.2%(w / w)总蛋白,94.2%(w / w)总糖,4.6%(w / w)无机盐组成;主要成分为多糖PSG-2即一种小分子均质的蛋白质结合多糖。PSG-2的单糖分析显示,其由葡萄糖,甘露糖和果糖组成。因光滑球拟酵母CCTCC M202019为多重维生素营养缺陷型菌株,通过优化维生素混合物的含量,突变株4-C10在500mL烧瓶中在30℃下72小时发酵后多糖产量高达77.6g / L。为了进一步阐明机理,将突变株4-C10与原始菌CCTCC M202019进行转录水平研究,RT-qPCR分析显示,与野生型菌株相比,与多糖生物合成相关的一些关键基因的转录水平上调。接下来,他们将野生型菌株上两个最显著的上调基因CAGL0H02695g和CAGL0K10626g敲除,结果发现多糖的产量降低了18.0%,丙酮酸生产和底物转化率分别提高了11.2%和34.8%。该团队还指出,其他基因与RT-qPCR分析中多糖合成的关系可进一步研究,以增强丙酮酸生产的潜力。由此可见,ARTP作为比较基因组学的重要研究工具,可以有效的了解基因的功能,表达调控机制等。

文章精选内容如下:

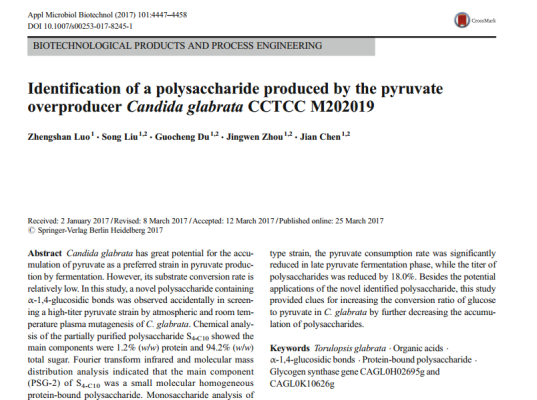

1、ARTP选育突变株4-C10的聚合物

Fig. 1 Culture broth of wild-type and strain 4-C10. a Culture broth of strain 4-C10 after 30 min. b Culture broth of strain 4-C10 (inverted) after 30 min. c Culture broth of CCTCC M202019 after 30 min. d The partially purified S4-C10 polymer from the culture broth of strain 4-C10

2、突变株4-C10的聚合物S4-C10分析

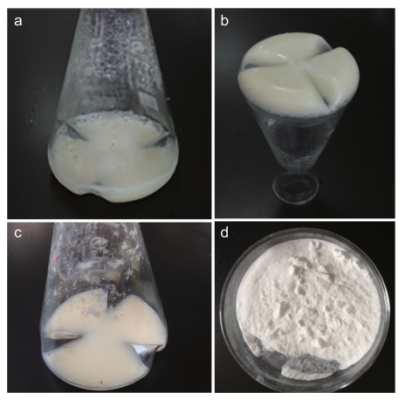

S4-C10主要成分为多糖的分析

Fig. 2 The infrared spectra and UV of the partially purified S4-C10 polymer. a An aqueous solution of S4-C10 polysaccharides was examined with a UV–visible spectrophotometer over a wave number range of 190–800 nm. b Infrared spectra of the dried S4-C10 polysaccharide in the KBr pellet were examined over a wave number range of 400–4000 cm

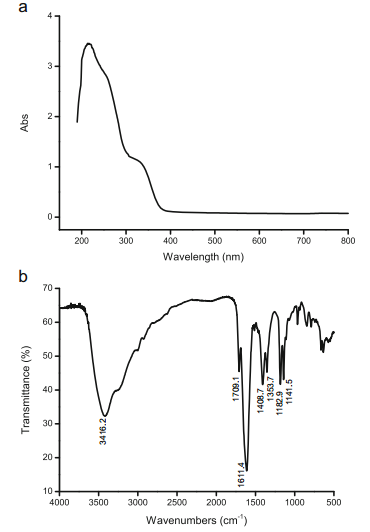

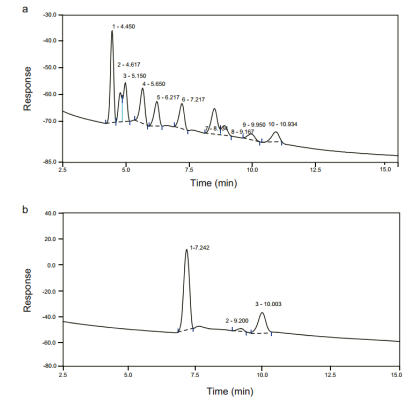

Fig. 3 Chromatography of the S4-C10 polymer on a Superdex 200 column detected by an AKTA purifier system. a The process of S4-C10 purification. Black and gray lines represent the absorbance at 210 and 280 nm; 1, 2...10 represent different components at different eluent times. Sequentially eluting peak labeled PSG-1, PSG-2 from left to right at 210 nm. b The protein content of different samples at different elution times from the purification process with the AKTA purifier system (GE Healthcare, Houston, TX, USA) with water as the mobile phase at a flow rate of 1.0 mL min.

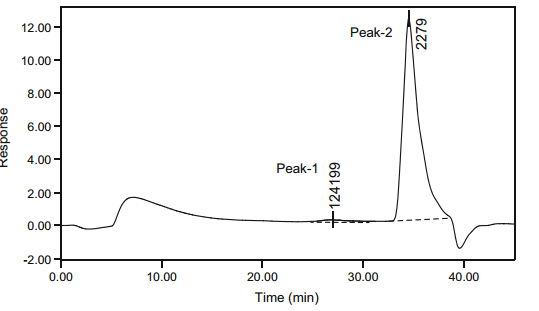

Fig. 4 Molecular mass distribution of the partially purified S4-C10 polymer. S4-C10 molecular mass distribution was measured by high-performance gel permeation chromatography

Table 1 Molecular mass distribution of the partially purified S4-C10 polymer

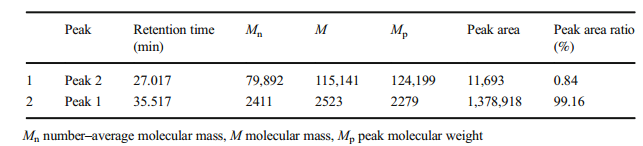

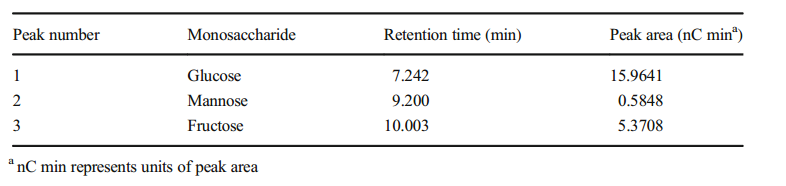

Fig. 5 High-performance anion exchange chromatography of the monosaccharide standards and monosaccharide acid hydrolyzed from polysaccharide PSG-2. a High-performance anion exchange chromatography of the monosaccharide standards. b Monosaccharides from acid-hydrolyzed polysaccharide PSG-2. The peak corresponding to the substance is shown in Table 2 and Table S3.

Table 2 Monosaccharidecomposition of PSG-2

3、维生素对发酵产生S4-C10的影响

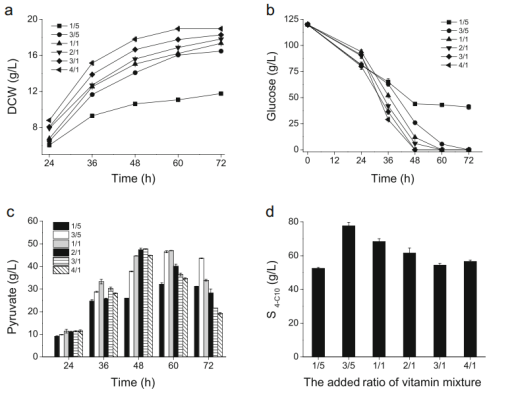

Fig. 6 Preliminary fermentation optimization of S4-C10 polysaccharide in vitamin mixture concentration. Polysaccharide fermentation was done at 30 °C with shaking at 220 rpm for 72 h with different concentrations of a vitamin mixture. a Time courses of DCW during the fermentation process. b Time courses of glucose during the fermentation process. c Change of pyruvate during the fermentation process. d Effect of the concentration of vitamin mixture on the content of S4-C10 polysaccharide after 72 h

4、与多糖生物合成相关的关键酶的转录分析

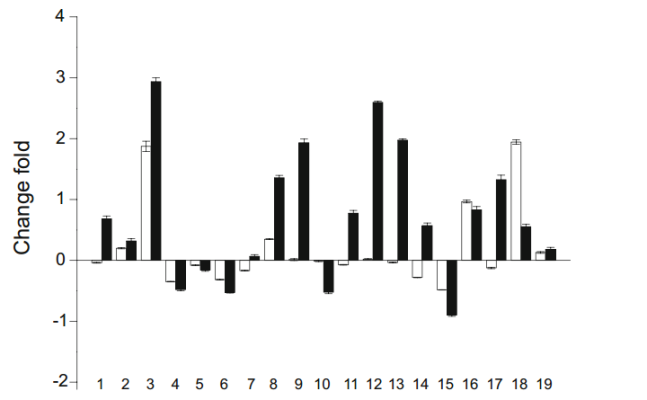

Fig. 7 Transcriptional analysis of key enzymes related to polysaccharide biosynthesis in mutants. Some key genes were chosen to analysis their transcriptional levels in mutants compared to that of the wild-type strain at the beginning of the stationary phase in seed culture (white bars in the figure) and pyruvate fermentation (black bars in the figure) process.1to19in the figure refer to CAGL0K03421g,CAGL0K07480g,CAGL0L02167g,CAGL0H07579g,CAGL0F00605g,CAGL0A04829g,CAGL0F04873g,CAGL0I10054g,CAGL0L01925g,CAGL0J06468g,CAGL0F04719g,CAGL0K10626g,CAGL0H02695g,CAGL0G01034g,CAGL0G04851g,CAGL0K00583g,CAGL0K04037g,CAGL0L08184g,andCAGL0M13827g,respectively.

5、敲除CAGL0H02695g和CAGL0K10626g对丙酮酸和多糖的产生的影响

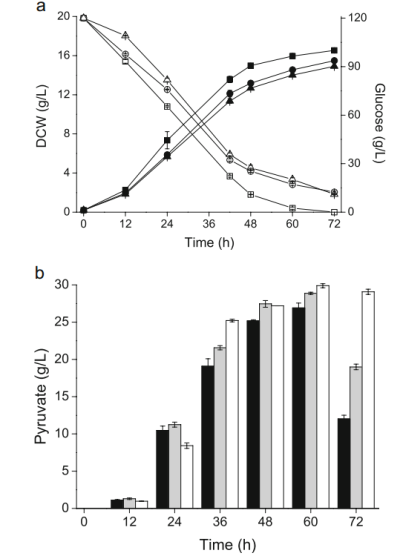

Fig. 8 Effect of knocking out CAGL0H02695g and CAGL0K10626g on pyruvate production in C. glabrata. Wild-type C. glabrata was fermented with T.GΔarg8 (CAGL0H02695g::ARG8) and CGΔarg8Δura3 (CAGL0H02695g::ARG8; CAGL0K10626g::URA3) at 30 °C in a 500-mL flask with shaking at 220 rpm for 72 h. a The change of glucose and DCW in the fermentation process. Glucose (C. glabrata, open square; CGΔarg8 (CAGL0H02695g::ARG8), open circles; CGΔarg8Δura3 (CAGL0H02695g::ARG8; CAGL0K10626g:: URA3), open triangle); DCW (C. glabrata, black squares; CGΔarg8 (CAGL0H02695g::ARG8), black circles; CGΔarg8Δura3 (CAGL0H02695g::ARG8; CAGL0K10626g::URA3), black triangle). b The change of pyruvate in the fermentation process. Pyruvate (C. glabrata, black bars; CGΔarg8 (CAGL0H02695g::ARG8), gray bars ; CG Δa r g8Δ ura3 ( CAGL0 H 02695 g : : ARG8 ;CAGL0K10626g::URA3), white bars)

本文由天木生物整理,中文内容仅供参考,一切内容以英文原文为准。欢迎转发朋友圈,如需转载或获取原文,请邮件info@biobreeding.com。